Standards save lives

The pictograms for the standards show which hazards the PPE protects against. The letters and numbers stated below the pictogram represent the specific protective performance.

Raw materials and garments are subjected to various in-house tests in addition to these legal requirements. Due to our work in standardisation committees and collaboration with technical colleges and certification bodies, our staff constantly keep abreast of developments and expand their knowledge of standards.

Do I need multi-risk protective clothing?

The answer to this question is a clear “it depends” as the key factor is the relevant area of application.

This type of protective clothing is intended to protect the wearer against weld spatter (small splashes of molten metal), short-term contact with flames as well as radiant heat from the electric arc. Under normal welding conditions, it offers limited electrical insulation against electric conductors of up to 100 V DC. This standard sets out two classes with specific performance requirements (class 1 is for lower requirements, class 2 for higher requirements).

This international standard specifies the minimum requirements for clothing protecting against heat and/or flames. In a wide variety of fields of application, the wearer can also be exposed to convective, radiant or contact heat, as well as splashes of molten metal. Within the standard, letters A-F define the performance levels relating to the protective properties listed above.

This type of protective clothing is intended to protect the wearer against thermal effects of a defined electric fault arc and prevents continued burning. The clothing protects the wearer against a certain type of heat in connection with an electric arc. The heat can be convective and radiating, caused by splashes of molten metal, or also a combination of the two aforementioned hazards. The tests of material and clothing are carried out either in accordance with IEC 61482-1-1 (determination of the ATPV value, respectively the ELIM value) or in accordance with IEC 61482-1-2 / EN 61482-1-2 ("box test"). The tested protective clothing does not replace electrically insulating protective clothing such as clothing in accordance with EN 50286:1999, „Electrically insulating protective clothing for work on low-voltage installations“. Complete personal protection also requires suitable protective equipment such as safety helmet/visor, protective gloves etc. Since 2020, the standard has a harmonised European edition EN 61482-2:2020; the reference was published in the Official Journal of the European Union (OJEU) in March 2021.

This type of protective clothing is intended to protect the wearer against thermal effects of a defined electric fault arc and prevents continued burning. The clothing protects the wearer against a certain type of heat in connection with an electric arc. The heat can be convective and radiating, caused by splashes of molten metal, or also a combination of the two aforementioned hazards. The tests of material and clothing are carried out either in accordance with IEC 61482-1-1 (determination of the ATPV value) or in accordance with IEC 61482-1-2 / EN 61482-1-2 ("box test"). The tested protective clothing does not replace electrically insulating protective clothing such as clothing in accordance with EN 50286:1999, „Electrically insulating protective clothing for work on low-voltage installations“. Complete personal protection also requires suitable protective equipment such as safety helmet/visor, protective gloves etc.

This Standard specifies material and design requirements for electrostatic dissipative protective clothing used as part of a total earthed system, to avoid incendiary discharges. In the context of this European Standard, a total earthed system is one in which personnel and other conductors are connected to earth via a resistance of less than 10^8 Ω. The material and design requirements may not provide sufficient protection in oxygen enriched flammable atmospheres.

EN ISO 20471 sets out the requirements for high visibility clothing which is capable of visually signalling the user's presence. The high visibility clothing is intended to provide conspicuity of the wearer in any light condition when viewed by operators of vehicles during daylight conditions and under illumination of headlights in the dark. This standard specifies performance requirements to be met by the protective clothing in terms of colour and retro-reflection, along with minimum surface dimensions and requirements to be met by materials used in the smallest possible garment size.

Specifies requirements and test methods for materials and seams used in clothing to protect against precipitation (e.g. rain, snowflakes), fog and ground humidity. Waterproofness and resistance to water vapour are the properties that must be tested and indicated on the label. The various classes for resistance to water vapour provide an indication for the recommended wearing time in different ambient temperatures.

This standard specifies the minimum requirements to be met by protective clothing against chemicals offering limited protective effect, including reusable protective clothing. Protective clothing against chemicals offering limited protective effect is for use where there is a possibility of exposure to minor chemical spraying, liquid aerosols or low-pressure spattering.

This European Standard specifies requirements and test methods for the performance of garments for protection against the effects of cool environments above−5°C.

The Standard sets out requirements and test methods for the performance of clothing ensembles for protection against the effects of cold environments equal to or below −5°C.

The European standard 13758-1 defines the method for determination of permeability of ultraviolet solar radiation for textiles; EN 13758-2 sets out the classification and identification of the clothing. As solar radiation causes skin diseases, only covered surface areas are protected of type UV-A and UV-B radiation.

PlatzhaltertextThis Standard specifies methods of test and minimum performance requirements for protective clothing to be worn in wildland firefighting and associated activities.

This Standard specifies physical and performance requirements, methods of test and marking requirements for industrial safety helmets. Industrial safety helmets are intended primarily to provide protection to the wearer against falling objects and consequential brain injury and skull fracture.

In EN 166 are defined the functional requirements for various types of personal eye-protectors against various hazards, such as those occurring in industry or in laboratories, and it contains basic requirements for eye protection such as the size of the minimum field of view, flammability, UV resistance or protection against dust and liquid metal splashes.

This European Standard specifies requirements, test methods, marking and information to be supplied for protective gloves against the mechanical risks of abrasion, blade cut, tear, puncture and, if applicable, impact.

In the standard are described the test methods, general requirements, levels of thermal performance and the marking for protective gloves against heat and/or fire. Gloves intended to protect the hands against heat and/or flames can be tested according. Test methods include one or more of the following; fire, contact heat, convective heat, radiant heat, small splashes or large quantities of molten metal.

EN 511 specifies the requirements and test methods for gloves which protect against convective and conductive cold.

EN ISO 20345 specifies basic and additional (optional) requirements for safety footwear used for general purpose. It includes, e.g. mechanical risks, slip resistance, thermal risks, and ergonomic behaviour.

Clothing tested according this standard is suitable for the manufacture of products, which are sensitive to discharges of 100V or more. Persons with ESD protective clothing are therefore protecting products during the manufacturing process from electrical discharges, which can happen with clothing that is not suitable for ESD, e.g. through friction or electrostatic induction (magnetic field, field effects) and/or material separations, and are therefore preventing damage to the component.

RIS-3279-TOM (formerly GO-RT 3279) is a high visibility standard for the rail industry in the UK and sets out the minimum requirements for high-visibility clothing that must be worn by staff when on the lineside or on or near the line.

Cleanliness classes

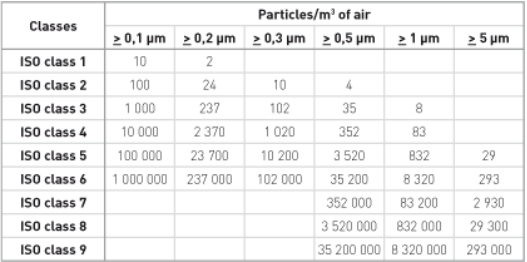

The cleanroom is a room under a controlled atmosphere (filtration, overpressure) in which contamination is reduced as much as possible. The cleanliness class of a cleanroom is determined by measuring the particle concentration of the specified particle sizes in the air. The results show whether the particle concentrations do not exceed the limit concentration of the respective particle sizes. In this way, the purity classes can be determined.

Depending on the model processing, other cleanroom classes are achieved by the finished product. Due to the production process, the cleanroom suitability of the finished garments must be established by a suitable laundry service provider before use.