The turn of the year brings important changes for European sustainability policy. Several key regulations have been adjusted in terms of timing, clarified in terms of content, or politically realigned in order to reconcile ambitious environmental and due diligence goals with practicable implementation requirements for companies. A clear trend is emerging: less bureaucratic burden for small and medium-sized enterprises, while focusing on large market players with corresponding influence along global value chains.

A key set of rules in this context is the EU Deforestation Regulation (EUDR). In order to give companies more time to set up the necessary traceability and documentation systems, the start of application has been postponed by one year. For large companies, the regulation will now apply from December 30, 2026. Small and micro-enterprises benefit from an extended deadline until June 2027. In addition to the new timetable, significant simplifications have been agreed upon in order to reduce the administrative burden in a targeted manner. For example, the obligation to submit a due diligence statement now lies exclusively with market participants who place relevant raw materials or products on the EU market for the first time or make them available on the market. Only the first downstream participant must also collect the reference numbers, while this obligation is completely waived for the rest of the downstream supply chain. Nevertheless, the goal remains clear: anyone who imports raw materials such as wood, rubber, or coffee into the EU makes a significant contribution to global resource conservation by proving that their supply chains are deforestation-free.

At the same time, European guidelines on sustainability reporting and corporate due diligence were further specified. On December 16, 2025, the agreement on the so-called Omnibus I package, which had previously been reached between the EU Commission and the EU Council, was officially approved. This created the political framework for simplifications to the Corporate Sustainability Reporting Directive (CSRD) and the Corporate Sustainability Due Diligence Directive (CSDDD). The aim is to focus the requirements more strongly on large companies while reducing administrative burdens along the supply chain. Even though the final text of the amendments and publication in the Official Journal of the European Union are still pending at the turn of the year, the main adjustments are considered to have been politically decided. The planned changes relate in particular to the definition of companies subject to reporting requirements, the phasing-in of the application, and simplifications in data collection within supply chains.

The CSRD focuses on companies with an average annual net turnover of at least €450 million and 1,000 employees. The aim is to relieve small and medium-sized enterprises in particular of disproportionate bureaucratic requirements. The reporting obligation will start in 2028 for the 2027 financial year. For small and medium-sized enterprises with fewer than 1,000 employees that are not subject to reporting requirements, the Voluntary Sustainability Reporting Standard for Non-Listed Small and Medium-Sized Enterprises (VSME Standard) provides structured guidelines that enable the standardized and proportionate provision of sustainability information. Companies subject to reporting requirements may only request information from smaller suppliers on the basis of this standard.

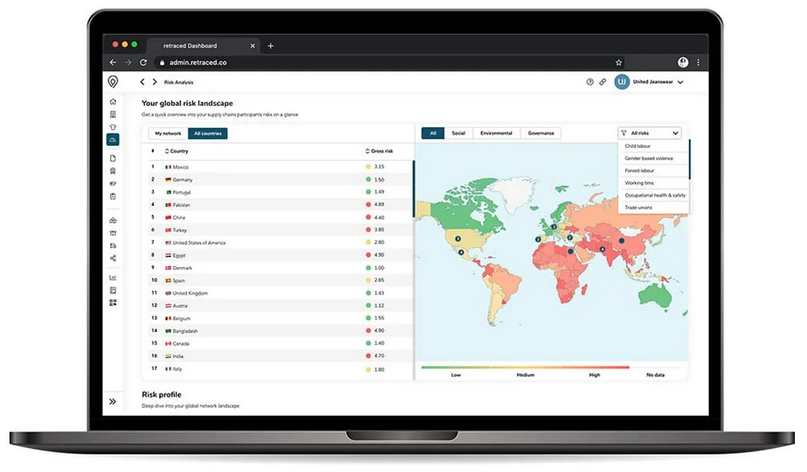

In future, the CSDDD will only apply to very large companies with more than 5,000 employees and a minimum turnover of €1.5 billion. Although the regulation primarily addresses major market players, indirect effects on supply chains are still to be expected, particularly with regard to risk analyses, preventive measures, and cooperation with business partners. The directive must now be transposed into national law by July 26, 2028.

At the national level, France is also taking additional steps. Since January 1, 2026, PFAS have been banned in certain consumer goods there. The areas of personal protective equipment (PPE) and safety and emergency services are exempt from this regulation until December 31, 2029. The legislator is thus taking into account the special protective function of these products and at the same time creating a temporary transition period for the development of suitable alternatives.

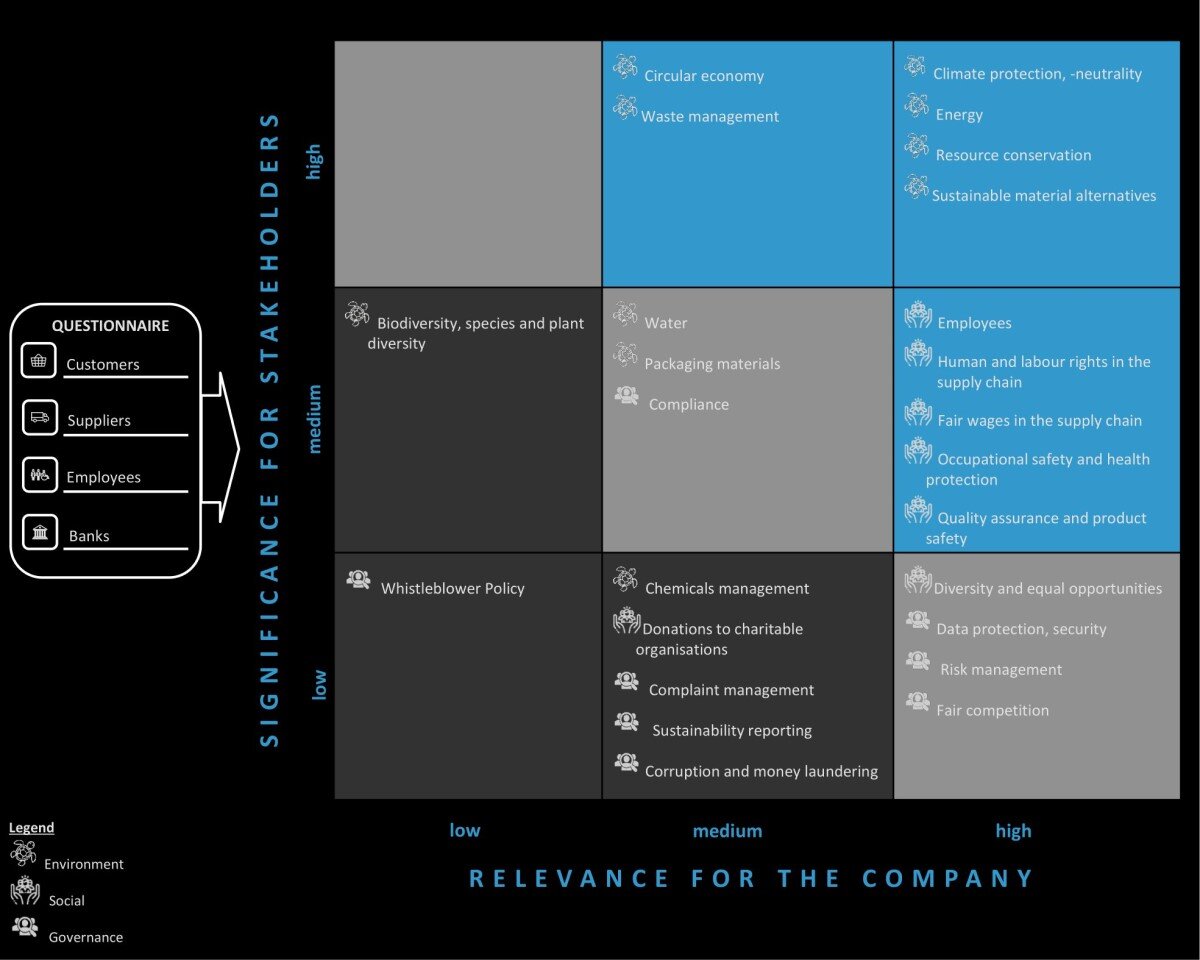

Current legislative developments show that the European Union is consistently pursuing its sustainability course, but at the same time making it more differentiated and risk-based. Extended transition periods, clearer responsibilities, and a more targeted approach to very large companies are intended to effectively anchor environmental and human rights standards without creating unnecessary administrative burdens along supply chains. For companies, this means greater planning security and less burden on the one hand, while on the other hand, strategic engagement with sustainable supply chains, transparent reporting, and regulatory requirements remains a key success factor for the coming years. For HB Protective Wear as a medium-sized company, these regulatory developments have only a limited impact, as most requirements primarily affect very large companies and certain raw materials. Nevertheless, this phase is now being used to review processes with regard to supply chains, reporting obligations, and regulatory requirements, to identify potential for optimization, and to systematically embed sustainability where it makes sense and is feasible.